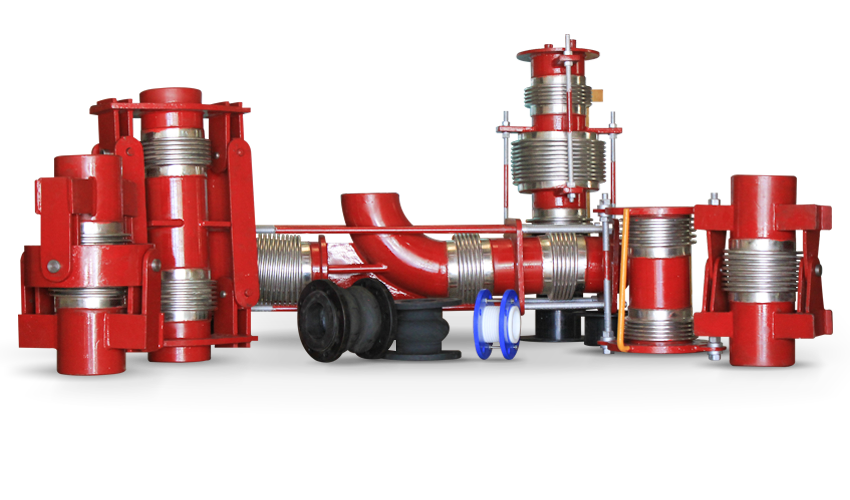

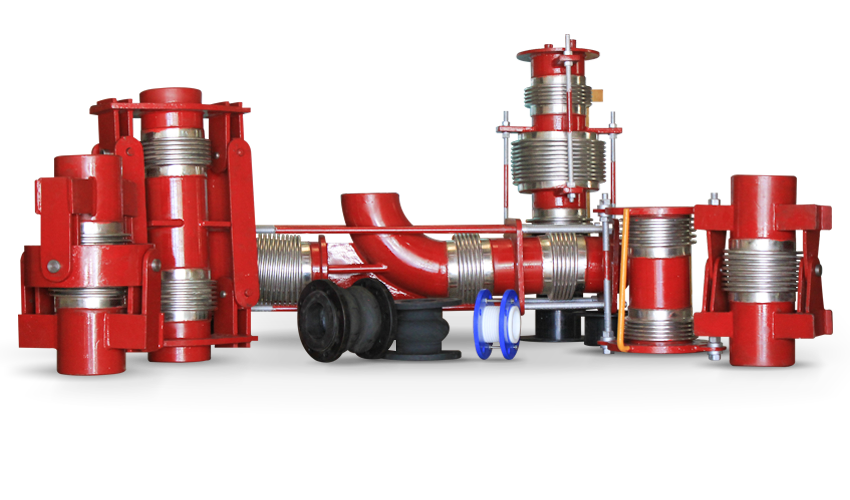

Types of Expansion Bellows

There are several kinds of expansion bellows made for certain uses. The most popular types of expansion bellows are made of metal, rubber, or fabric. Selecting the appropriate type for your system is crucial because each has distinct qualities and applications.

Metal Expansion Bellows

Expandable metal bellows are extensively utilized in high-temperature and high-pressure settings. They are constructed out of sturdy metals, such as stainless steel. These bellows are perfect for power plants, refineries, and chemical plants because of their exceptional strength and flexibility.

Rubber Expansion Bellows

Rubber expansion bellows are ideal for applications that need to absorb vibrations and be flexible. They are frequently found in industrial machinery, water treatment facilities, and HVAC systems. Rubber bellows can be used in a variety of applications because of their chemical resistance.

Fabric Expansion Bellows

Bellows for fabric expansion are utilized in low-pressure settings where flexibility is essential. They are constructed from synthetic textiles, fiberglass, and PTFE. For ducting systems in ventilation, exhaust, and flue gas systems, these bellows are perfect.

Applications of Expansion Bellows

Bellows for expansion are multipurpose and utilized in several sectors. They control pipeline thermal expansion in the oil and gas sector. They are used in power plants to safeguard turbines and boilers. They are necessary for duct flexibility in HVAC systems. They are also essential in water treatment facilities, maritime applications, and chemical processing.

Benefits of Using Expansion Bellows

The use of expanding bellows has many advantages. They lengthen the life of piping systems by lowering the possibility of damage from thermal expansion. Bellows reduce noise and vibrations, increasing operational effectiveness. They also save money and time by making maintenance and installation simpler.

How to Choose the Right Expansion Bellow

Choosing the appropriate expansion below requires taking a number of things into account. Ascertain your system's operating temperature and pressure levels. Considering the chemical exposure, select the right material. Think about the area needed for installation and the movement needs. Making the ideal decision for your application can be ensured by consulting a specialist.

Maintenance and Care for Expansion Bellows

The longevity of expansion bellows depends on proper maintenance. Frequent inspections aid in identifying wear, corrosion, and fatigue indicators. Ensuring optimal performance involves cleaning the bellows and inspecting for leaks. System problems can be avoided by rapidly replacing defective bellows.

Expansion Bellows are essential parts of many industrial systems. Making the best choice for your needs requires an understanding of their types, applications, and benefits. Your systems' lifespan is increased and their efficiency is guaranteed by proper maintenance. For every industrial application, purchasing premium expansion bellows is a wise choice.