Reduce Ship Operating Costs: Maintain Your Marine Compressor Effectively

Marine Compressors

Introduction:

In the competitive world of maritime shipping, every penny saved contributes to a healthier bottom line. Marine compressors are the workhorses of a ship, keeping temperatures under control for critical equipment and ensuring passenger and crew comfort. However, neglecting proper maintenance of these essential machines can lead to a domino effect of inefficiencies, driving up operational costs. Here's how a proactive approach to marine compressor maintenance can keep your ships running smoothly and save you money in the long run.

The High Cost of Compressor Neglect

A statistic from a 2020 study by the American Society of Mechanical Engineers (ASME) revealed that poorly maintained compressors can experience a 20% decrease in efficiency, leading to increased energy consumption and operational costs. This translates to a significant amount of money wasted over time, especially for ships that rely heavily on their compressors. (Source: American Society of Mechanical Engineers (ASME) - Performance Testing of Marine Refrigeration Systems

1. Tamrotor TMC 40/10 SA EWNA | Compressor

Maker : Tamrotor

Model : TMC 40/10 SA EWNA

Description : Compressor

Condition : Used & Removed From Working Environment

Ship Automation can supply new and refurbished parts for Tamrotor.

2. Hatlapa HSC 15 | Screw Compressor

Maker : Hatlapa

Model : HSC 15

Description : Screw Compressor

Condition : Used & Removed From Working Environment

Ship Automation can supply new and refurbished parts for Hatlapa.

3. Mitsubishi FA-2LSYM2 | Semi Hermatic Compressor

Maker : Mitsubishi

Model : FA-2LSYM2

Description : Semi Hermatic Compressor

Condition : Used & Removed From Working Environment

Ship Automation can supply new and refurbished parts for Mitsubishi.

4. Sabroe CMO 26 | Reciprocating Compressor

Maker : Sabroe

Model : CMO 26

Description : Reciprocating Compressor

Condition : Used & Removed From Working Environment

Ship Automation can supply new and refurbished parts for Sabroe.

5. Tanabe TASK1022 G3-J | Screw Compressor

Maker : Tanabe

Model : TASK1022 G3-J

Description : Screw Compressor

Condition : Used & Removed From Working Environment

Ship Automation can supply new and refurbished parts for Tanabe.

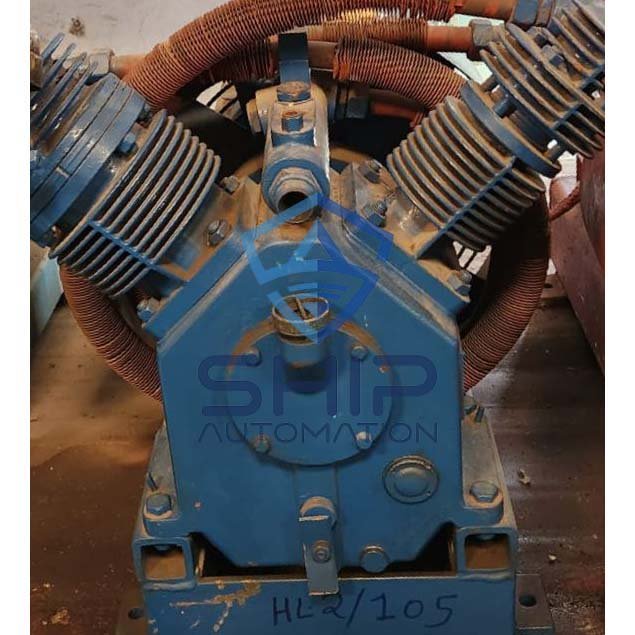

6. Sperre HL2/105 | Air Compressor

Maker : Sperre

Model : HL2/105

Description : Air Compressor

Condition : Used & Removed From Working Environment

Ship Automation can supply new and refurbished parts for Sperre.

7. Tanabe H-274 | Air Compressor

Maker : Tanabe

Model : H-274

Description : Air Compressor

Condition : Used & Removed From Working Environment

Ship Automation can supply new and refurbished parts for Tanabe.

8. Bock F16/1751 | Compressor

Maker : Bock

Model : F16/1751

Description : Compressor

Condition : Used & Removed From Working Environment

Ship Automation can supply new and refurbished parts for Bock.

9. Tanabe H-64 | Air Compressor

Maker : Tanabe

Model : H-64

Description : Air Compressor

Condition : Used & Removed From Working Environment

Ship Automation can supply new and refurbished parts for Tanabe.

10. Bitzer 2EC-2.2 40s | Semi – Hermatic Reciprocating Compressor

Maker : Bitzer

Model : 2EC-2.2 40s

Description : Semi – Hermatic Reciprocating Compressor

Condition : Completely Reconditioned

Ship Automation can supply new and refurbished spare parts of Bitzer.

11. Marine Bitzer VI | Refrigeration Compressor

Maker : Bitzer

Model : Bitzer VI

Description : Marine Refrigeration Compressor

Condition : Completely Reconditioned

Ship Automation can supply new and refurbished spare parts of Bitzer.

12. Marine Bitzer II | Refrigeration Compressor

Maker : Bitzer

Model : Bitzer II

Description : Marine Refrigeration Compressor

Condition : Completely Reconditioned

Ship Automation can supply new and refurbished spare parts of Bitzer.

Conclusion

By prioritizing the effective maintenance of your compressors, you're not just protecting vital equipment; you're making a sound investment in your ship's operational efficiency and overall profitability. A proactive approach to maintenance translates to lower energy consumption, reduced repair costs, and a safer operating environment for your crew. Remember, a well-maintained marine compressor is a cost-effective compressor, keeping your ship running smoothly and your bottom line healthy.

For expert advice on creating a customized marine compressor maintenance plan for your ship, contact our team of experienced professionals at Ship Automation today. We can help you optimize your compressor performance and ensure your ship operates at peak efficiency, saving you money in the long run.

What's Your Reaction?